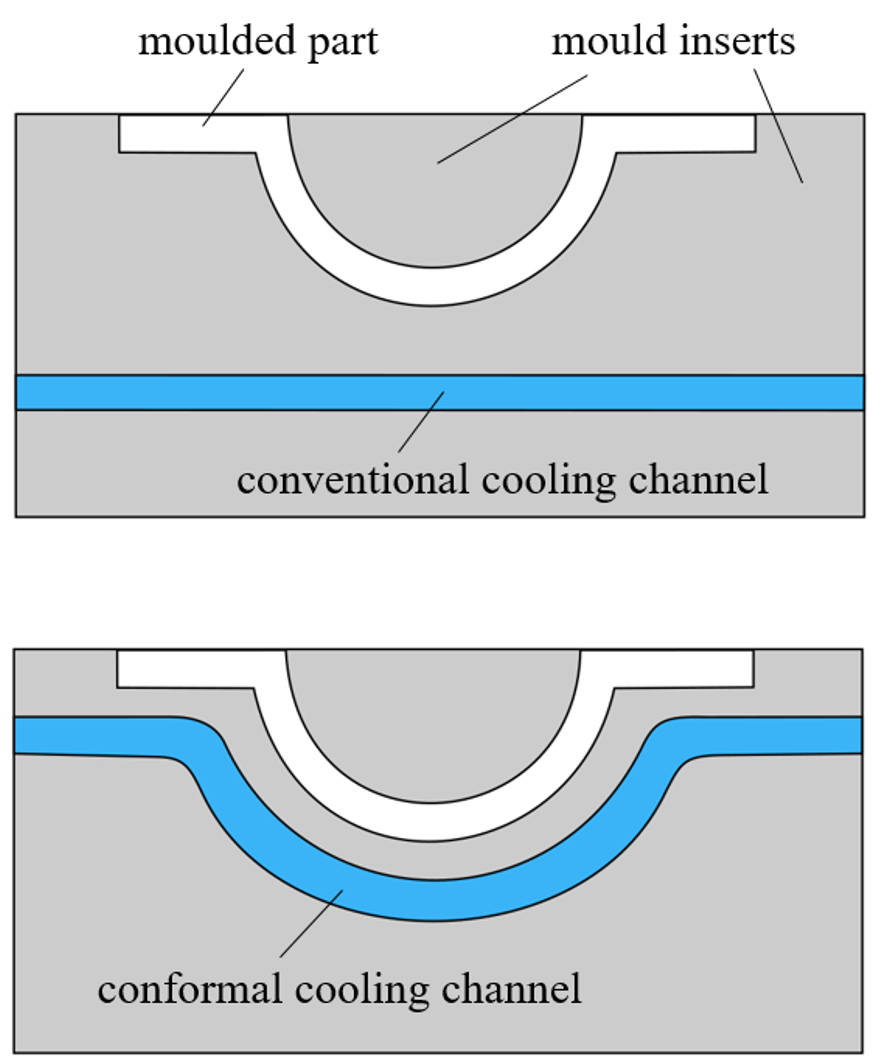

What is CONFORM?

CONFORM is an acronym for a project titled “Development and Performance Analysis of Sustainable Conformal Cooling Channels”. This project is being worked upon by a Research Support Officer I and a number of supervisors with the Department of Industrial and Manufacturing Engineering at the University of Malta. This project is funded by the Transdisciplinary Research and Knowledge Exchange Centre (TRAKE), an EU-funded programme.

The CONFORM project is a multi-disciplinary project which focuses on polymer engineering and sustainability.