The automotive industry uses a great deal of materials to build vehicles. These materials have evolved greatly over the decades as new manufacturing technologies have emerged and also the much stricter CO2 emissions allowed by the European Commission. It follows that car manufacturers are continuously pursuing the design and manufacture of lighter materials for various car components such as structural parts and drivetrain components so as to increase speed and power.

Researchers within the department are using various heat treatments and surface engineering techniques to improve the properties of materials aiming to reduce the overall vehicle weight. Ongoing work use the state of the art equipment housed in the DMME laboratories to study the fatigue, impact and hardness properties as well as the wear performance under various lubrication conditions. This study will provide better insight on the suitability of such surface engineered materials for use in automotive components.

Laser Shock Peening for Automotive Austempered Ductile Iron Gears (LaSPAAG) is a multi-disciplinary project which proposes the use of laser shock peened (LSP) austempered ductile iron (ADI) as a replacement for heavier carburised steel automotive gears. In this project, the optimum laser process parameters will be determined by studying the physical interaction between the laser beam and the ADI surface, modelling the residual stresses and characterising the material. These parameters will then be used to determine the resultant mechanical and tribological characteristics. Finally, the identified process will be applied to compare LSP ADI gears to industry-standard automotive power transmission steel gears.

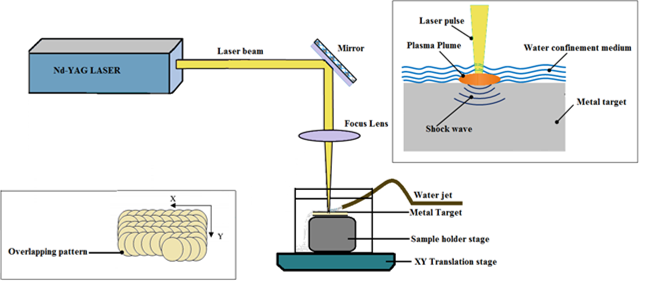

Schematic diagram of laser shock peening (LSP) process set-up.

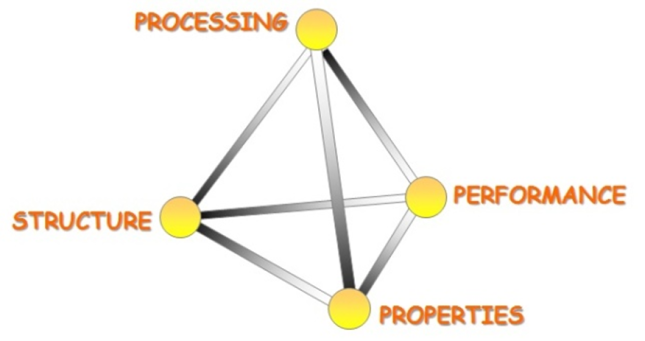

Integrated project plan follows sp3 materials science tetrahedron approach.

Follow us on:

Austempered ductile iron (ADI) is a material which is used for automotive applications. When ADI engineering components require high toughness and ductility at the core of the component coupled with high bending fatigue strength and good tribological characteristics at the surface, the ADI can be first austempered in the higher temperature range of 350–400°C to obtain upper ausferrite. It is subsequently engineered to improve the surface properties and obtain the fatigue and tribological characteristics required by the intended application, using surface engineering processes such as shot peening (SP). The SP process is constantly maturing, and many questions still remain open as the industry is continuously on the search for process improvements that improve and extend the service lifetime of components.